VIGC-member event: Electronics in labels & packaging

Labels and packaging are successful graphic products. Both Intergraf (the European federation for print and digital communication) and Finat (the European trade association for the label industry) report a continuous increase in sales of labels and packaging products since 2010. The name “smart” appears frequently in the labels & packaging market. Smart labels and packaging are equipped with additional functionalities such as interaction with a smartphone, registration of product data (temperature) and logistical functions. The thematic event “electronics in labels and packaging” highlighted innovations in this area.

Introduction in “printed electronics”

In preparation for the speakers’ afternoon there was the opportunity to subscribe for an introduction course in “printed electronics”. After all, the name “printed” continues to cause confusion: are graphic companies going to print electronics? Which inks and printing technology can be used? What applications are on the market? A number of questions and challenges that seems to be relevant, proven by the attendance.

The speakers

The theme afternoon was opened by Jordi Baeta, Market Development Manager RFID / Intelligent Labels at Avery Dennison (https://www.averydennison.com/en/home.html). He explained technical distinctions between RFID (Radio Frequency Identification) and NFC (near field communication). RFID uses a dipole antenna to send & receive data using radio waves. NFC uses a single coil structure to retrieve energy from the smartphone (induction) and use it to communicate data. Interesting background information is the increasing use of RFID in the automotive sector: car manufacturers use this to guarantee the authenticity of supplied parts (you don’t want to buy a car with fake parts!). The future plans of Avery Dennison give a clear indication of how strongly this company believes in contactless communication with labels. There is the collaboration with PragmatIC (https://www.pragmatic.tech/). PragmatIC is a pioneer in the production of flexible RFID chips, inexpensive and very suitable for label applications. Williot (https://www.wiliot.com/), experts in passive Bluetooth communication, has caught their attention. Their concept is interesting: we are surrounded by a multitude of electromagnetic radiation (Wi-Fi networks). With the Williot antenna, energy is harvested from this radiation to control a Bluetooth application (smart label).

Tijl van Vliet is the Co-Founder & CTO of TicTag (https://tic-tag.com/). The interesting thing about the Tictag is that they have developed an inexpensive (patented) alternative to NFC under the name “multitouch”. The concept is a conductive printed pattern that can be integrated into a label. By bringing the label in contact with the touch screen of your smartphone, data can be transferred from label to app or web page. What happens is that the contact simulates a multiple fingerprint on the touch screen that can be recognized by the app or web page. According to Tijl, 2 million variable codes can be generated with these 5 contact points. Possible applications can be found in product authenticity, services for consumers, logistics, … Tijl shared his opinion on competing technologies such as the QR code and NFC tags. Safety remains an issue with QR codes. In a Dutch city a payment system was set up by using QR-codes that were glued on city bicycles. I didn’t take long before the codes were overlapped with new (counterfeited) QR-codes. For China Tijl doesn’t expect an increasing use: NFC is an American based technology that is sensitive issue in China in the current business climate. It can explain the growing use of QR codes in China. An advantage for the “multitouch” can be its intuitive use: nothing unexpected happens. You are in control: you make the physical contact with the touchscreen of your smartphone and receive the feedback through the app or web page.

One of the major challenges for the future is the high-volume production of smart packaging. Jarne Machiels, project engineer at IMO-IMOMEC (Hasselt University) reported on the European Paperonics (https://www.uhasselt.be/UH/IMO/Projects/Paperonics.html) project. Goal of the project is to research production of “smart systems” on paper carriers. The development of 3 demos is planned: a “smart” marketing packaging, an anti-counterfeiting packaging and a packaging with temperature registration. The first test results of screen printed NFC antennas on different paper types were shown. Flexo and rotogravure are the following printing techniques that will be investigated.

After these technically inspired speakers it was time for commercial applications. Jonas Vandecruys, Functional decoration specialist at AB InBev (a major beer brewer), gave insight into the views of the brand owner regarding smart packaging. The challenge for AB Inbev is that it does not actually know the end consumers of their product (beer). They deliver to retail, cafés, restaurants, etc., but the actual consumer is a “black box” for them. The functional “Budweiser Cup” was a successful campaign in the United States but remained unknown here. In this drinking cup, which was offered to supporters during the World Cup in the States, a functionality was added at the bottom of the cup: the higher the noise level at the stadium, the more the bottom lit up. This effect was very appreciated by the spectators and perfectly illustrates what AB InBev requires of ‘smart packaging’: customer experience is king. They are not that happy with the dominant role of the smartphone and try to move the customer’s attention away towards the product experience. The cost price remains a difficulty for mass adaptation, while important investments are needed to come to working concepts (the chicken and the egg story). Nevertheless, AB InBev continues to follow developments closely: collecting data through smart packaging is the new gold!

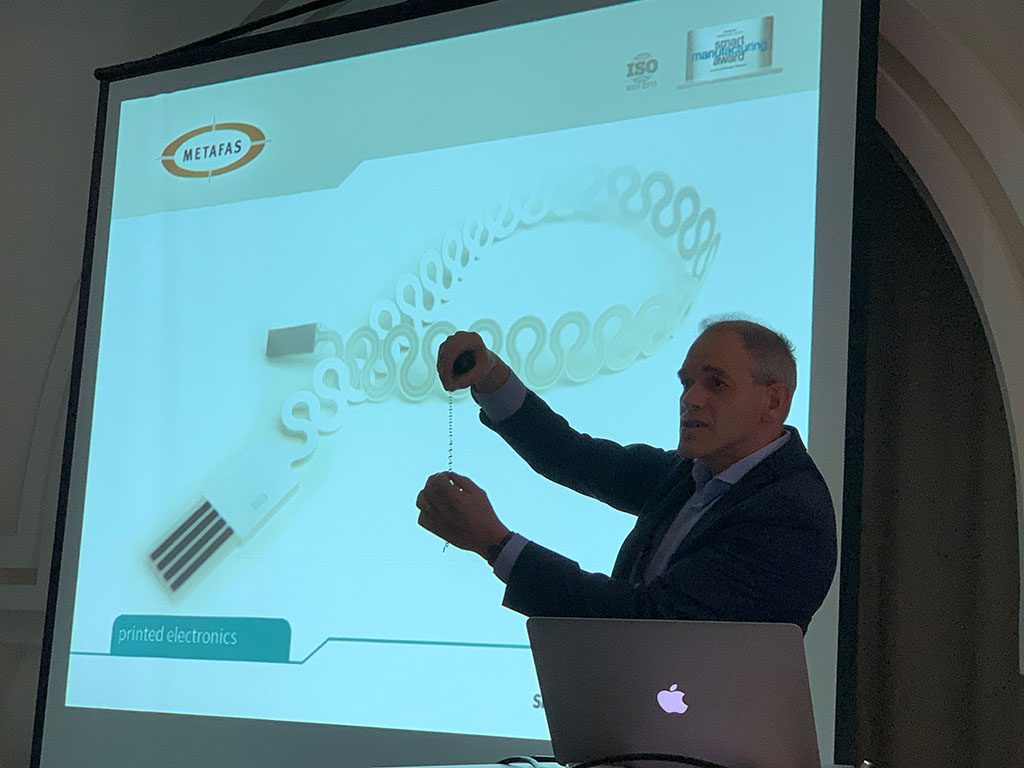

Closing speaker of the event was Hans van de Mortel, owner of Metafas. Metafas prints “smart products” and thereby strongly focuses on innovation. The product portfolio includes RFID antennas, printed speakers, LED applications, smart textiles, thermoforming and smart pharmaceutical packaging. The portfolio and professional experience have resulted in collaborations with the Holst research center, hospitals and the car manufacturer TESLA. Hans has the good characteristic of naming things the way they are: if you want to make money with printed electronics, then his advice is a good start!

Conclusions

The objective of the event was to provide insights in the integration of electronics in packaging and labels. Clear trends:

- The smartphone, with its large distribution and use, continues to provide innovations, also in print. Beside NFC tags, touchscreen communication from label to smartphones is in the pipeline.

- Brand owners are not all keen on the increasing use of the smartphone. In a countermovement, they design concepts to take the consumer’s focus away from the smartphone and shift it to the brand product itself.

- Energy remains a key element in these new forms of communication. NFC can be supplied with power through induction. Passive Bluetooth is a new interesting battery-free concept.

- Costs remains important in development of smart labels and packaging, additional costs need to be justified.

Thanks to all the speakers and attendees for making this event a success!